Advanced Manufacturing Technologies for Forming, Machining, and Assembling with Al-Mg-Sc Alloys offer a groundbreaking solution originating from recent advancements in materials science and manufacturing processes. Developed by leading organizations specializing in aerospace engineering and advanced manufacturing, these technologies leverage the unique properties of Al-Mg-Sc alloys, which have been recently commercialized. These alloys boast exceptional characteristics such as extra-low density, specific mechanical properties, high fracture toughness, and outstanding corrosion resistance.

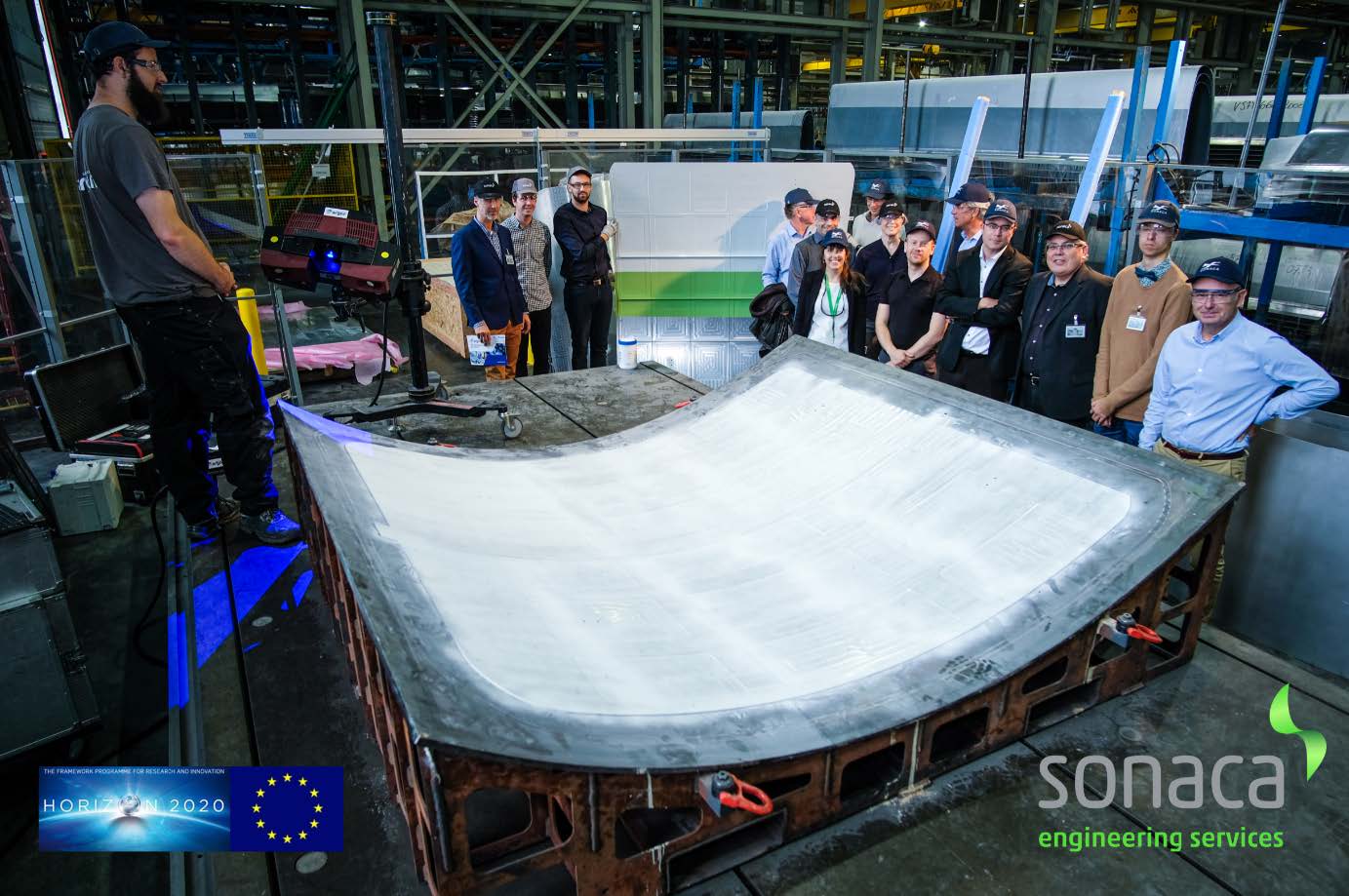

The application of these advanced manufacturing technologies is diverse, encompassing various processes including welding, forming, and machining. Particularly noteworthy is their compatibility with the “integral structure” concept, aimed at simplifying assembly operations, reducing weight, and minimizing lead times in manufacturing applications. Projects like the Manufacturing of Integral Stiffened Skin Panels (MISSP) under Clean Sky 2 have demonstrated the successful utilization of these alloys. One of the key innovations of this technology lies in the presence of stable dispersoids generated by incorporating Sc and Zr into the alloy composition. This unique feature prevents recrystallization even at high temperatures, enabling easy welding and forming processes without compromising the material’s properties.

Furthermore, the combination of Al-Mg-Sc alloys with advanced manufacturing processes allows for the development of integral structures with significantly reduced connections, leading to substantial weight savings. The advantages offered by Al-Mg-Sc alloys are manifold, including low density, exceptional weldability, excellent damage tolerance, good corrosion resistance, creep formability, thermal stability, and ease of recyclability. These properties make them highly desirable for various industrial applications, especially in aerospace and related sectors. In seeking partnerships or collaborations, the goal is to further develop and implement these advanced manufacturing technologies. By leveraging the expertise and capabilities of potential collaborators, the aim is to drive innovation, optimize processes, and expand the applicability of these cutting-edge solutions in diverse industries.

- Developer: Sonaca