An industrial optical engineering firm from Belgium has developed and patented the phase-shifting Schlieren method, filling a niche in the range of optical measurement techniques. This submicron method almost reaches the resolution achieved by interferometric systems, but avoids their inherent limitations (cost, environment insulation, sensitivity & limited shape steepness). It has a variable sensitivity, both high in spatial (in-plane) and height (out-of-plane) resolution. At the same time, it does not suffer from vignetting, digitization effects or sample positioning; and it is auto-calibrated.

This method can be used for detecting surface shape, quality, defects and inhomogeneities of transparent objects, thin films, gas-liquid interfaces and reflective surfaces. Partnerships are welcomed, both for direct use or integration of the technology, and for dedicated application or development of the method into a product.

Advantages

The Schlieren method itself is not new, and is popular due to:

- its relative ease of implementation,

- its low cost,

- its use of conventional optics and light sources,

- its variable sensitivity to fit the object under study,

- its robustness to vibrations (well adapted to industrial environment).

Combining Schlieren with phase-shifting methods leads to additional benefits:

- It has an inherent high in-plane resolution, which only depends on the spatial resolution of the camera detector.

- It provides a high out-of-plane resolution (0.002°), as phase-shifting provides a real measured gray values per camera pixel, without digitization or resolving effects limiting the resolution.

- The method does not suffer from small vignetting.

- The method creates large dynamic angular range, and thus the ability to characterize objects with large slopes.

Applications

The method is mature and has already been successfully applied to:

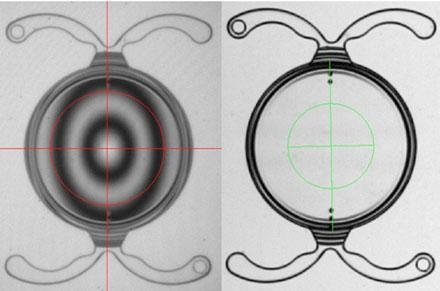

- perform in-line quality control of ophthalmic lenses,

- quantify shape and defects in glass spectacles,

- investigate multi-layered computer displays,

- visualize convection pockets at a gas-liquid surface,

- identify transparent material inhomogeneities,

- quantify flatness/polish of glass and mirrors.

- Developer: Open Source Management