Technology need

Summary of the technological need

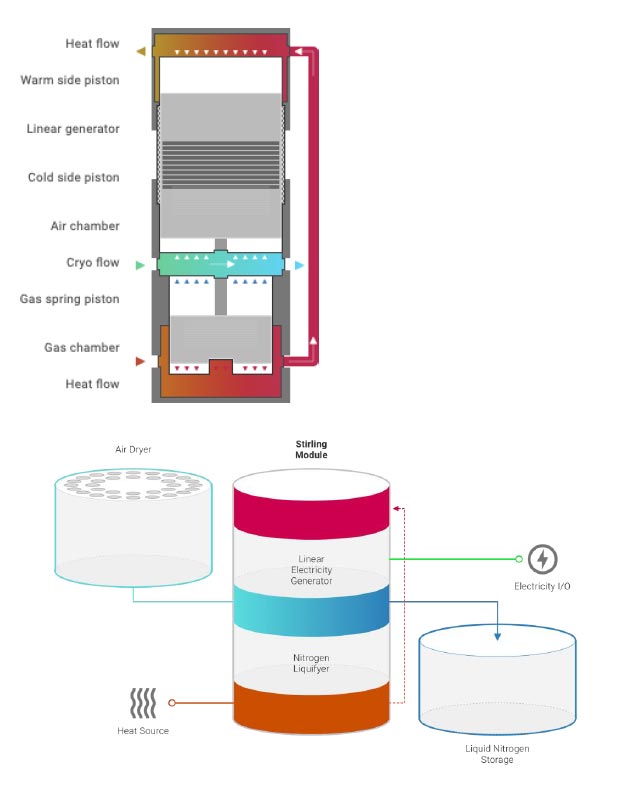

Technology for the materialization of a mass-market device that does energy harvesting and storage. Parts of it need to insulate really well, other parts need optimal conductivity.

Background

The Tricryo engine requires 3 different temperature zones on a small (< 1m) body; ranging between liquified nitrogen temperatures, ambient temperature and 523 K. Parts of the engine have a need for maximal conductivity, other parts require optimal isolation. The TriCryo engine consumes excess energy sources in order to convert, store and manage the output of energy on demand. The energy sources range from renewables and netpower to excess heat. The storage time spans from smart direct conversion to seasonal storage. The engine is designed as a modular, cylindrical enclosure with low maintenance need and a long lifespan. The unit consists of only a few moving parts and is aimed to be built with durable materials. The goal is to mass-produce the engine for a consumer and prosumer market, limiting the total production cost to EUR 2,5K or less per unit. TriCryo will be marketed directly as contender of the battery wall segment as Tricryo HOME; capitalising the USP’s of longevity, higher capacity, low risk and non-toxic materials. The battery wall segment already sold 100.000+ units in Germany alone, and is widely expected to grow dramatically over the next years but with structural issues -battery shortages and fire incidents- at the competitors side. TriCryo PRO approaches the prosumer and innovative industry with an explorative attitude. Our goal is to establish joint ventures with industry drivers through collaborative pilots with the mindset to improve energy yields and cost reductions in their respective market segments. In the first 3 years of operation, TriCryo aims to offer an “install & forget” circular service rather than direct sales of units. This way, we have the opportunity to harvest big data for our machine learning capabilities.

Application domains

Specifications

One of the main challenges is the discovery and implementation of both temperature resistant, conductive and isolating materials on a relative small structure. The heat delta ranges between 77 K and 523 K.

Research of optimal application and strategic planning in design stages are a first step. 4 design generations are planned, over a timespan of 3 years.

Further info regarding technical performance

The technological impact is centered on efficiency. The more efficient, the higher the converted output. The marketability threshold of the product is related to this technical performance.